Process Engineering

The pillar of process engineering encompasses the areas of expertise that focus on the design, development, and optimization of manufacturing processes. This field plays a key role in ensuring that production is carried out efficiently, cost-effectively, and sustainably while maintaining product quality and workplace safety.

One of its primary goals is to analyze and improve manufacturing processes to reduce waste, optimize resource utilization, and enhance productivity. Achieving this requires the application of modern engineering methods and techniques that facilitate process simplification and minimize errors.

This area of expertise includes the design of production lines and workstations, as well as the optimization of material flow, logistics, and supply chain processes. Engineers collaborate with experts from other fields to ensure efficiency and quality at every stage of the manufacturing process.

Additionally, process engineering encompasses continuous improvement processes aimed at the constant monitoring and fine-tuning of manufacturing operations. The introduction of new technologies, automation of production processes, and consideration of sustainability aspects all contribute to enhancing competitiveness.

Process engineering closely collaborates with product design to ensure the technological feasibility of products and the seamless integration of manufacturing processes.

Engineering support for processes

The task of engineering support for processes is to provide engineering and operational management support for the evaluation processes involved.

It focuses on industrial and research tasks that assist in ensuring the compliance of a specific process component with defined expectations.

The objective of this area of expertise is to implement cost-effective, reliable, and quality-assured processes within the framework of process engineering support.

Possible areas:

- measurement and monitoring of processes,

- process evaluation and analysis,

- development solutions,

- operational organization tasks,

- process optimization,

- capability assessments,

- efficiency and effectiveness issues,

- resource management issues.

Content of related services:

- process analysis,

- development and process management,

- comprehensive process engineering support.

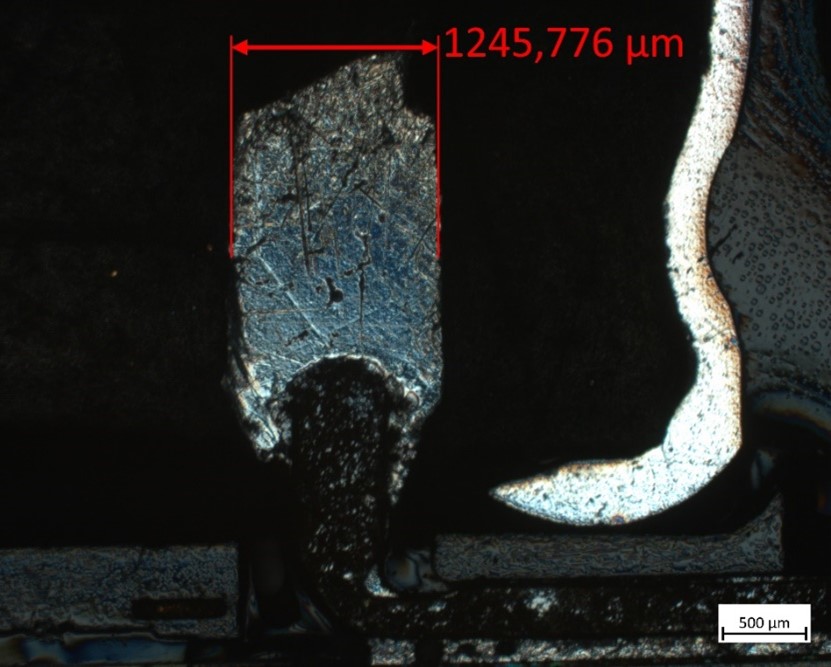

Testing technologies

The service area focused on testing procedures primarily offers solutions to testing and validation questions related to products or the product manufacturing process.

It targets industrial and research tasks that seek to address testing requirements arising in connection with a specific product or manufacturing process.

The objective of this area of expertise is to develop procedural proposals related to the emerging tasks or to adapt available procedures to achieve the defined testing objectives.

Possible areas:

- evaluation and determination of product characteristics,

- evaluation and determination of technological characteristics,

- analysis technologies,

- development of testing methods,

- enhancement of existing procedures,

- technical solutions for implementing testing procedures,

- establishment of testing know-how.

Content of related services:

- parameter analyses,

- development of testing procedures,

- development of testing technology,

- support for the implementation of testing procedures.